-

About UsProductsCustomized SolutionProjectGalleryNews

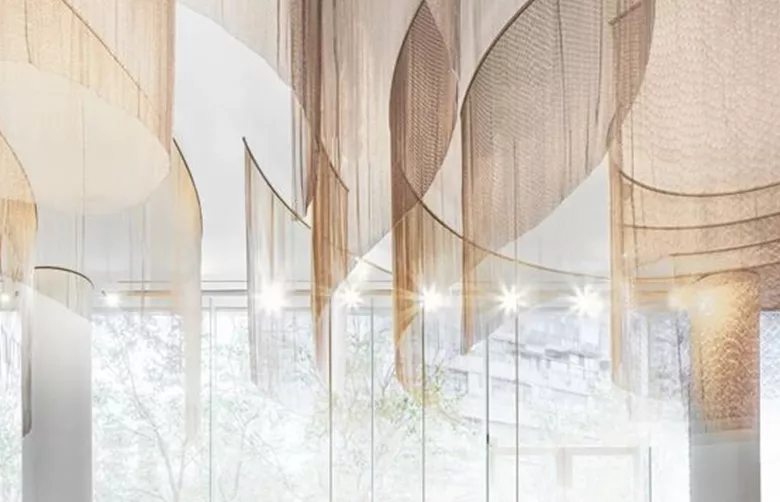

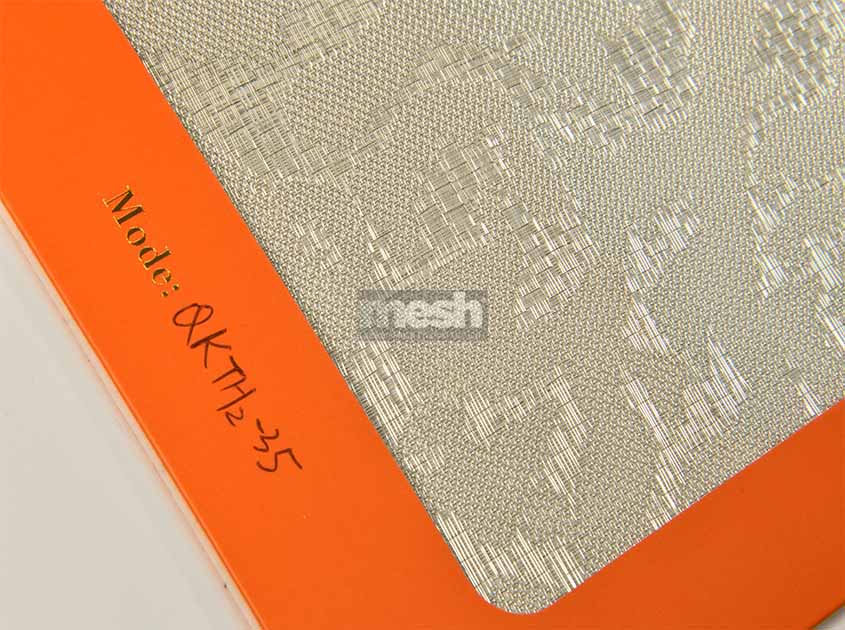

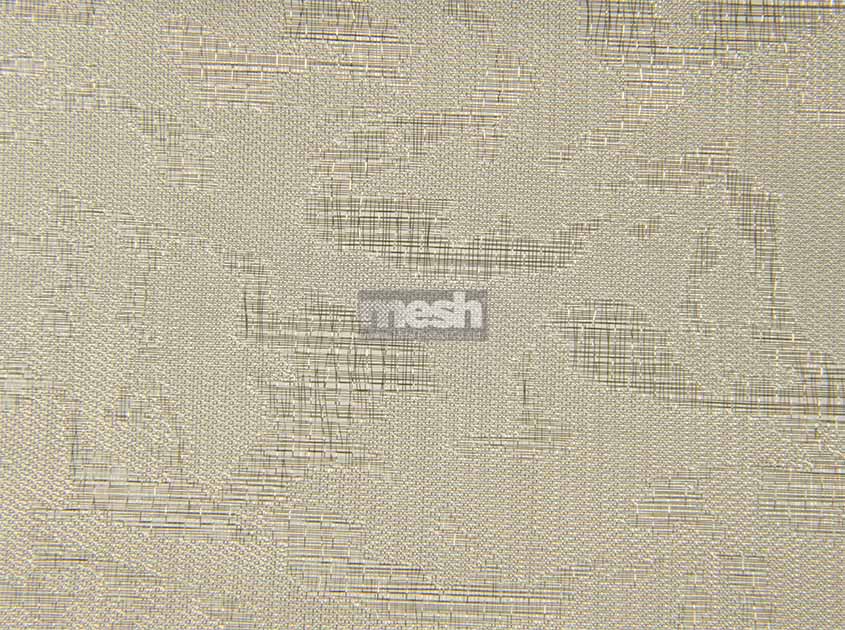

The Role of woven Metal Interiors supplier in Quality Control and Testing

Release time: August 14, 2023Quality standards and specifications

The woven Metal Interiors supplier first priority in quality control and testing is to ensure that the woven metal interiors comply with the relevant quality standards and specifications. They are responsible for supervising and managing the entire production process, from raw material procurement to final product manufacturing, to ensure that every link meets quality requirements. A woven Metal Interiors supplier needs to work closely with manufacturers and ensure that their products and production processes comply with national and industry standards in order to provide high-quality woven metal interiors.

quality control process

Woven Metal Interiors supplier plays a key role in quality control and testing, they are responsible for developing and executing the quality control process. This includes developing standardized inspection and testing procedures to ensure product quality and consistency. A woven Metal Interiors supplier needs to establish strict quality control standards, and conduct regular sampling and testing of products to ensure that they meet the specified requirements. They are also responsible for tracking and recording quality data and taking corrective action to resolve any quality issues.

Supply Chain Management

Another important role of woven Metal Interiors supplier in quality control and testing is supply chain management. They need to cooperate with other partners in the supply chain, such as raw material woven Metal Interiors supplier and manufacturers, to ensure the quality consistency of the supply chain. The woven Metal Interiors supplier is required to review and evaluate potential woven Metal Interiors suppliers and ensure they meet quality requirements. They also need to establish a good communication and cooperation relationship with the woven Metal Interiors supplier to ensure that any quality issues are resolved in a timely manner and to maintain the stability and reliability of the supply chain.

Continuous Improvement and Innovation

The woven Metal Interiors supplier's role in quality control and testing also includes continuous improvement and innovation. They need to constantly seek new quality control methods and technologies to improve product quality and performance. A woven Metal Interiors supplier should be actively involved in R&D and innovation activities, cooperating with manufacturers to jointly develop new products and solutions. They should also work closely with customers to understand their needs and feedback in order to further improve product quality and meet customer expectations.

Through the discussion of the role of woven Metal Interiors suppliers in quality control and testing, we can see that they play a vital role in ensuring the quality and consistency of woven metal interiors. They are responsible for ensuring that products meet quality standards and specifications, developing and implementing quality control processes, managing quality consistency in the supply chain, and continuously improving and innovating to provide premium braided metal interior products.

Recommended News